Ultra SL R Research & Development

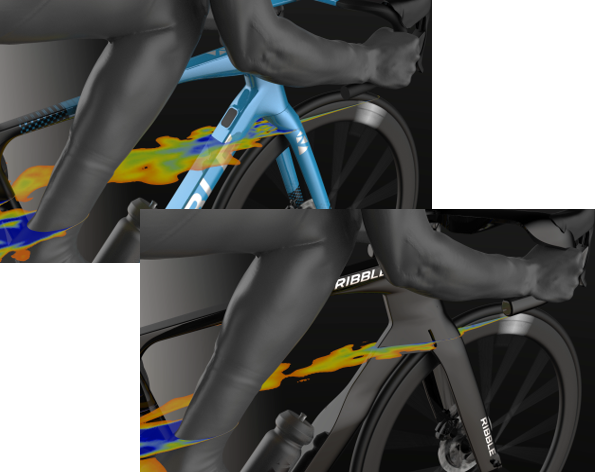

We wanted to develop a platform that would give every rider a performance advantage, not just the professionals. Because a bike needs to perform in the real world, in ever-changing real-life conditions, every test was run at two speeds; everyday rider (22mph) and pro rider 29mph and across a full YAW sweep of 0-20°, including +ve and -ve, through CFD analysis. Some like to test their bikes in isolation. This only tells part of the story though, so we designed and tested with bike and rider throughout the process and used a mix of body profiles; male, female and mannequin to ensure all riders, of all levels, shapes and sizes would experience the exhilarating performance advantage it has been engineered to deliver.

The first component that hits the air and is directly upstream of the rider is the handlebars, so this was a key place to look for aerodynamic gains. It soon became clear that conventional bar designs were a significantly limiting factor in performance potential.

Our innovative direct mount brake lever attachment system enabled us to optimise the bar shape for maximum performance gain, both aerodynamically and ergonomically. As well as being designed to give a measurable airflow advantage, the new cockpit has been engineered to give the rider better control, comfort and maintain a more aerodynamically optimised riding position for longer, the textured finish to the drops also ensures maximum grip without the need for traditional handlebar tape, further enhancing the aerodynamic performance too.

The Ultra cockpit has been designed entirely around rider and bike interaction, adding wake generators to the underside of the bars to create a Drag Reduction zone (DRZ) for the rider to sit in, resulting in a net drag reduction of around 2.1% for bike and rider. This translates to an average 23.2-second advantage over a full YAW sweep at 22mph over 40km vs the already aerodynamically optimised LEVEL 5 set up.

The handlebar dimensions have also been carefully selected, with bar widths at the hoods (tapering wider at the drops) ranging from a Pro spec 33cm for the rider looking for maximum aero performance to 36cm and 38cm across other cockpit size options. This promotes a more aerodynamic riding position, giving the rider a further significant aero gain in addition to the gains stated in this project report.

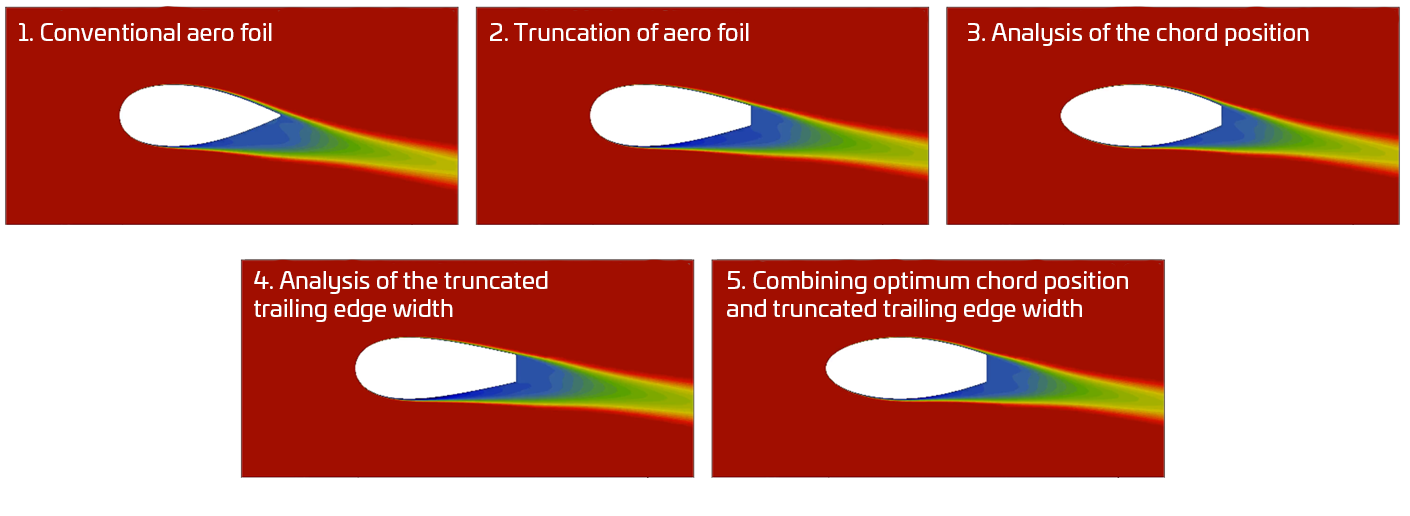

Every tube profile of the Ultra has been analysed and tested across truncation, chord, and trailing edge to create the optimum shape to perform across all YAW conditions.

The frame and forks shape, length and width are designed to ensure optimal airflow attachment along the surface of the tubes for as long as possible throughout the full YAW sweep, to reduce the amount of drag generated.

The upper downtube, through multiple design iterations, showed by combining the optimum chord position with the exact truncated trailing edge dimension delivered a true performance gain consistently across the full YAW sweep. The downtube was further optimised around a water bottle being fitted to mirror real world riding behaviour and actually proved to be faster with a bottle, than without. The airflow interaction between the fork and downtube profile proved so harmoniously efficient that from 10° of YAW, the tube profile in fact starts to generate thrust, helping to push you, rather than pull you back.

All designed within UCI regulations. Awaiting approval.

To read more about the Ultra SL R R&D story, download our ultra development process paper.

Download Paper